Top-notch services

Why Us ?

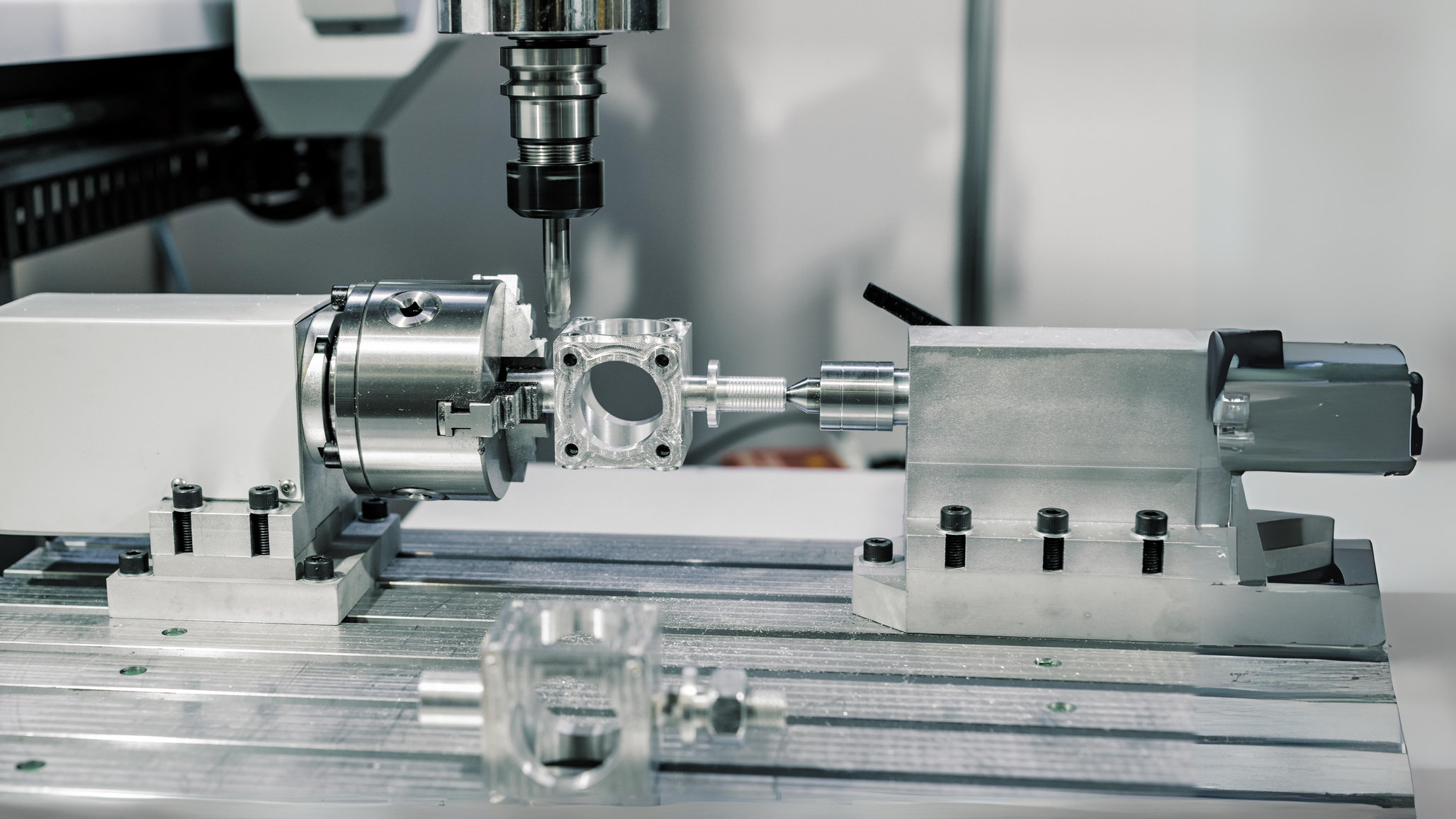

Welcome to Perfect L, where precision meets excellence in metal manufacturing. We stand as a beacon of craftsmanship and innovation, specialising in the meticulous creation of metal precision components. With a foundation rooted in cutting-edge technology and seasoned expertise, we craft components that exceed industry standards. From intricate designs to flawless execution, our engineers and technicians work tirelessly to bring concepts to life with utmost precision and accuracy.

Utilizing advanced machining techniques such as CNC milling and turning, we transform raw metal materials into refined components, ensuring exacting tolerances and uncompromised quality. Beyond mere manufacturing, our commitment extends to comprehensive quality checks and inspections at every stage of production, guaranteeing durability, functionality, and reliability in the final product.

Our firm thrives on delivering excellence and reliability in every component produced. Partner with us and experience the pinnacle of metal precision manufacturing, where craftsmanship and innovation converge to shape the future of industries worldwide.

Mission, Vision, Values

Misson

Provides effective solution to solve customers’ problem.

Vision

To develop lasting client relationships by providing reliability and trust

Values

High quality products delivered punctually.

Specialize in

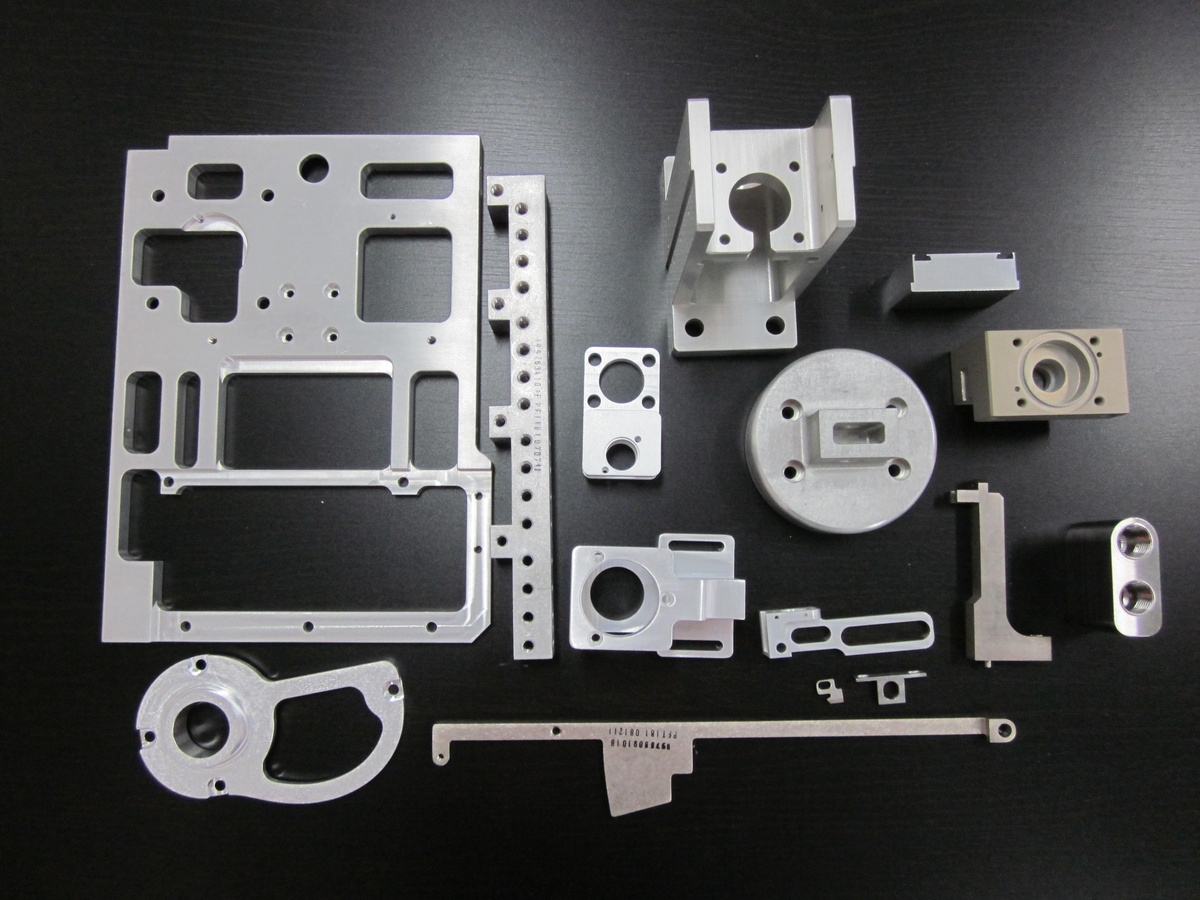

Manufacture of metal precision component

- Creating metal precision components involves meticulous design and advanced machining

- Engineers craft detailed plans for the components

- High-tech machining techniques are used to shape raw metal with precision

- Additional treatments may be applied for strength or aesthetics

- Rigorous inspections are conducted to ensure the final product meets strict standards for accuracy and durability.

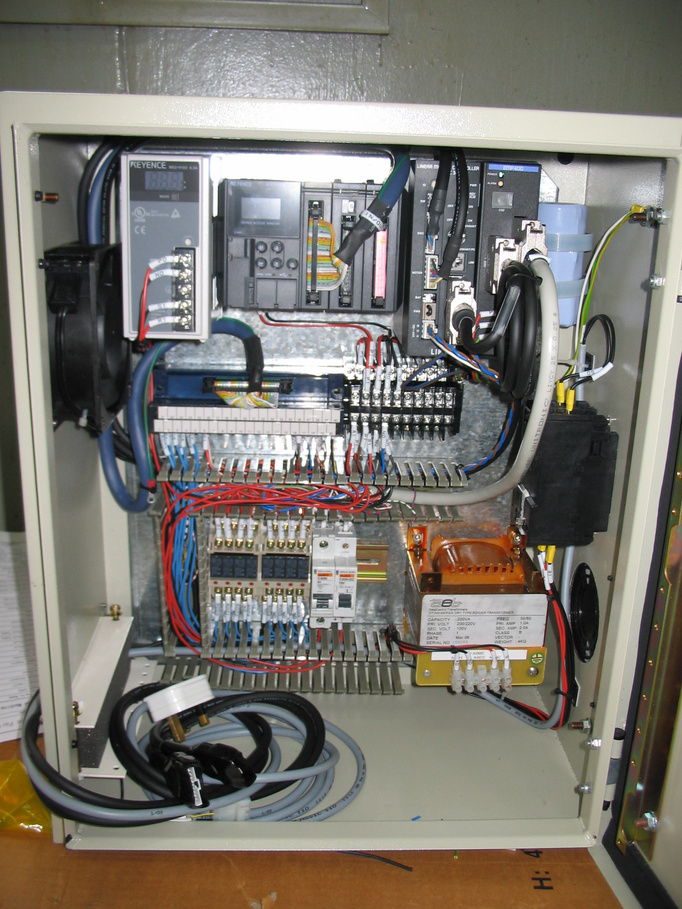

Assembly and Testing of component

- Component assembly involves precisely piecing together parts according to specifications

- Specialised tools are used to ensure precision

- Rigorous testing is conducted to verify functionality, durability, and performance

- The process ensures the reliability and quality of the final product

Services

Specialise in:

- High mix: low volume - many drawing low quantity

- Low mix: high volume

Induction Brazing

What is it?

The process of using heat to bond two or more metals together using a filler metal. Getting the optimum temperature of different metals with precise control to create intricate parts.

Stainless steel to Brass brazing

Samples

Stainless steel to copper brazing

Here are the types of induction brazing combinations we have done.

What we can do?

We have the ability to join metals of two different materials together, regardless of the coefficient of expansion.

Stainless steel to Stainless steel brazing

Copper to copper brazing

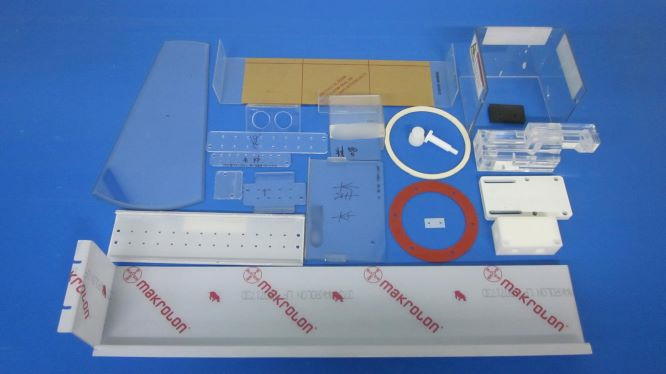

Plastic Bending

What is it?

What we can do?

Shaping plastic materials to meet specific design requirements involves the application of heat and pressure. Smoothing the edges is essential to avoid any rough or sharp edges.

Examples

We can accurately control the temperature to align with the melting point of different plastics, preventing discoloration, uneven surfaces, and the formation of bubbles.

Molding the plastic by bending it at various angles to meet the customers' requirements or design.

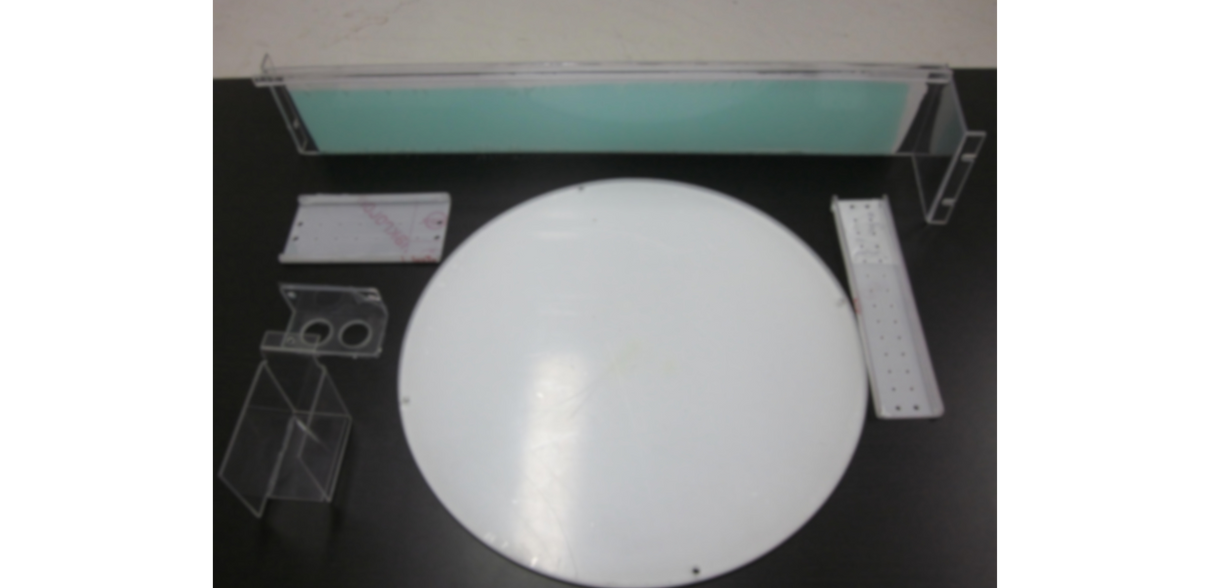

Plastic Machining

What is it?

Manufacturing precise engineering plastics tailored to customer requirements using CNC (Computer Numerical Control) machines.

Prototype sample using 3D printing

Prototype

We offer customers prototypes of the parts they request for manufacturing. These prototypes are created using 3D printing, allowing customers to review and approve the design before finalizing the production of the parts.

What we can do?

We have the capability to perform plastic machining on a range of plastic materials including Derlin, PVC, Nylon, Pow, Peek, Polycarbonate, and Arcylic.

Reverse engineering

What is it?

Utilizing a Coordinate Measuring Machine (CMM) to generate precise drawings with measurements for the parts we are tasked to produce.

What we can do?

The complexity and size of the item can affect the time needed to obtain precise measurements.

Process:

1

Original product

from customer

2

3D scanning using CMM

3

Get drawing with accurate measurements of product

4

Create prototytpe

5

Confimation with customer

6

Manufacture product

Other services

Services

Other services that we provide are:

- Polishing

- Fabrication

- Assembly

- customised products

Fabrication:

Production of metal components to suit customers’ needs

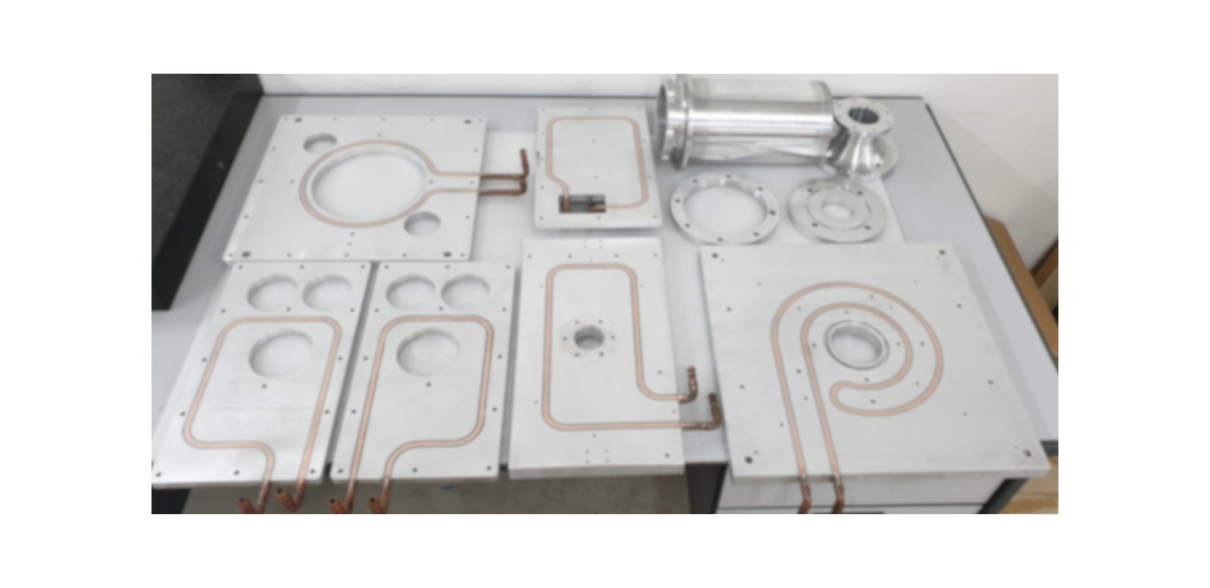

Cold Plate:

Customise product for our customers that uses it to cool down big machines

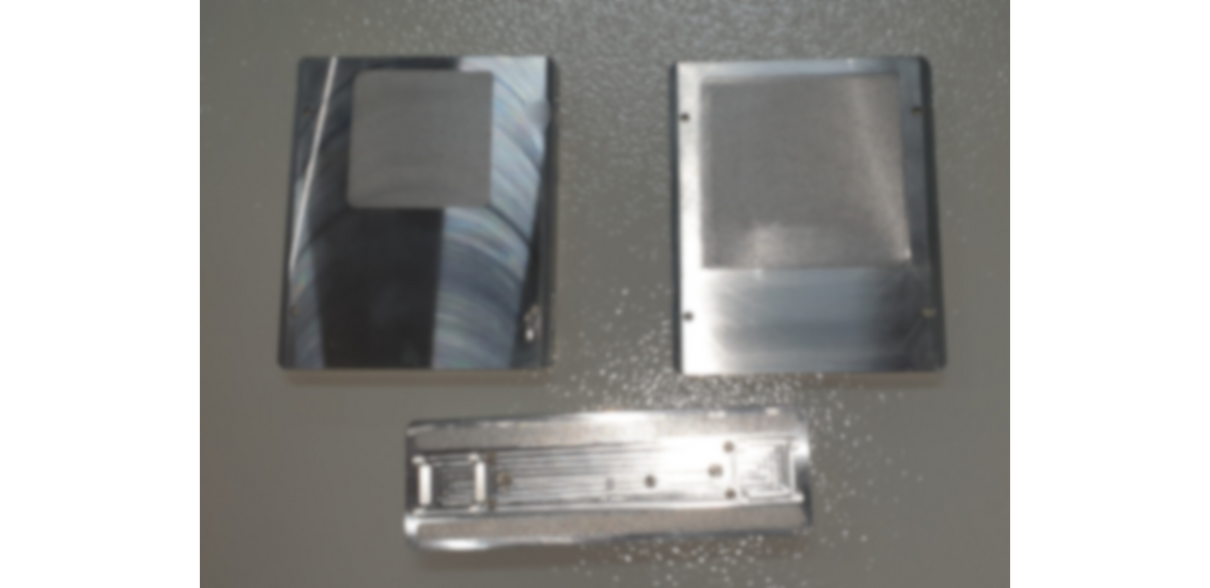

Vacuum Plate:

This product is designed to securely attach to the item, providing stability.

Carrier tray:

Design to meet customer needs and requirements

Polishing:

Makes surface smooth and shiny to enhance its appearance.

Assembly:

Arranging various components to match specific requirements

Fabrication: (Fly Wheel)

Manufacturing of small and intricate design components to suit the needs or products.

LOCATION

OFFICE HOURS

Monday to Friday

9:00 am to 5:00 pm

Weekends by appointment

© Perfect l technologies Pte Ltd